The 1990s ushered in the era of industrial technical screen printing and state-of- the-art technology. Since then, we have produced a variety of control panels for the household appliance industry using specially engineered machines. Our just- in-time approach to UV screen printing saves our clients valuable time while making housework easier.

As a second-generation owner-managed business specialising in UV screen printing, we have succeeded in growing sustainably in the market. We have also spent decades nurturing a family-like working atmosphere for our employees that has already given birth to many innovative solutions.

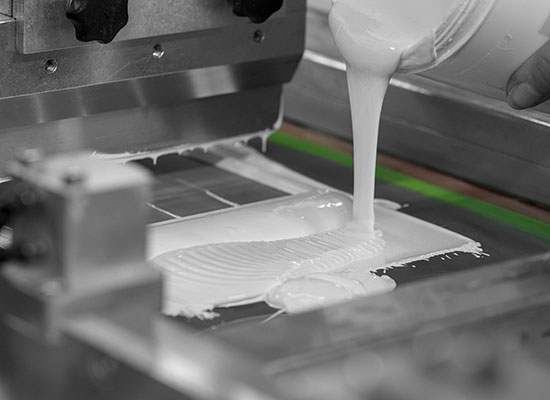

One example of our innovations is a “deep” drying process for colour layers that works with little to no solvents. All we needed to do was develop the right machine and equip it with a multifunctional dryer and various radiation technologies. Easy as pie!

Following a brief but intensive period of testing and development, we were able to start using our latest piece of equipment in 2019 – making us the only company in the industry to apply this innovative technique, even today.

The targeted deep drying of the ink layers results in a minimal amount of residual solvents and thus ensures maximum protection of the material with minimum production time.

We use materials that are specially coordinated to achieve the best possible results.

For the production of control elements in technical screen printing.

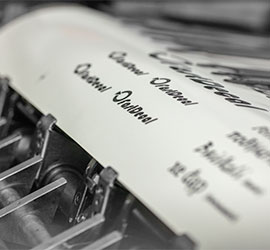

Control elements for the household appliance industry are produced on two printing lines using reverse printing.

Customer-specific components are printed just in time by us.

Semi-automatic and with fine adjustment. We print foil adhesive, signs, etc. and all this in the finest screen printing.

Print formats up to 500 x 700 mm /

max. 20 mm thickness

Our fully automatic stop cylinder of the brand SPS. We process material up to a thickness of 0.8 mm and a maximum sheet size of 500 x 700 mm. Due to the multifunctional equipment of this system we can print almost everything that meets the material criteria. We affectionately call this machine our "Swiss army knife".